Technical Projects Department

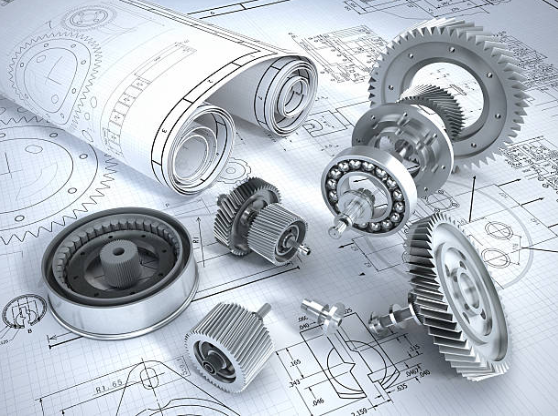

The construction of technological lines is one of the main divisions of our company. The responsibility for the order lies with the Project Engineers, starting from the concept and design phase, through the author’s supervision over the execution and implementation, as well as planning and implementation itself, to commissioning and after-sales service – creating a dedicated solution, created especially for a specific project.

In designing, we support with the Autodesk Product Design Suite Ultimate software, which includes: Inventor Professional, Autocad Mechanical, Autocad ReCap, Navisworks. We also use other dedicated engineering software.

We treat each order as a new challenge, we consider it individually and plan it to optimally implement it. We do not always create everything anew – we also make responsible and future adaptations of the existing state.

We are not only a producer, but we also feel responsible for the effective functioning of our devices during operation.

We carry out complete multi-industry projects and individual industry projects – mechanical, electrical, pipe, sanitary, and design of industrial devices and installations dedicated to individual applications.

A specific type of project is performance and security analysis for devices and their environment, which results in process automation to eliminate these threats and increase efficiency.

See more

At the measurement and quality control stages, we support 3D scanning with a Trimble SX10 total station, which records 3D data at a speed of up to 26.600 points per second, at a distance of up to 600m. The device is particularly useful when: